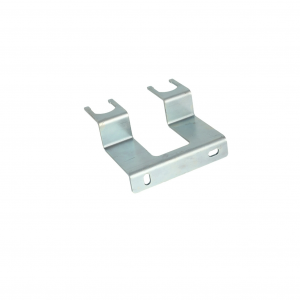

Amacandelo eAluminiyam eSiko eAluminiyam eSitampu

Inkcazo

| Uhlobo lweMveliso | imveliso eyenzelwe wena | |||||||||||

| Inkonzo yokuma enye | Uphuhliso lokungunda kunye noyilo-ungenise iisampulu-ibhetshi imveliso-ukuhlola-umphezulu unyango-upakisho-unikezelo. | |||||||||||

| Inkqubo | isitampu, ukugoba, umzobo onzulu, ukwenziwa kwamaphepha esinyithi, ukuwelda, ukusika i-laser njl. | |||||||||||

| Izinto eziphathekayo | carbon steel, steel stainless, aluminiyam, ubhedu, intsimbi yagalvanized njl. | |||||||||||

| Imilinganiselo | ngokwemizobo yomthengi okanye iisampuli. | |||||||||||

| Gqiba | Ukupeyinta ukutshiza, i-electroplating, i-hot-dip galvanizing, i-powder coating, i-electrophoresis, i-anodizing, i-blackening, njl. | |||||||||||

| Indawo yesicelo | Amalungu omatshini, iindawo zoomatshini bezolimo, iinxalenye zoomatshini bobunjineli, iinxalenye zobunjineli bokwakha, izincedisi zegadi, iindawo zoomatshini ezinobume bendalo, iinxalenye zenqanawa, iinxalenye zeenqwelomoya, ukufakwa kwemibhobho, iinxalenye zezixhobo zehardware, iinxalenye zokudlala, iinxalenye ze-elektroniki, njl. | |||||||||||

Iintlobo zesitampu

Sinikezela ngeqonga elinye kunye nenqanaba elininzi, ukuqhubela phambili kokufa, ukutsalwa okunzulu, isilayidi sesine, kunye nezinye iindlela zokutsibela ukuqinisekisa eyona ndlela isebenzayo yokwenza iimveliso zakho. Iingcali zeXinzhe zinokutshatisa iprojekthi yakho ngesitampu esifanelekileyo ngokuphonononga imodeli yakho ye-3D elayishiweyo kunye nemizobo yobugcisa.

- I-Progressive Die Stamping isebenzisa ukufa okuphindaphindiweyo kunye namanyathelo okwenza iindawo ezinzulu kunokuba zinokufezekiswa ngokufa komntu omnye. Ikwavumela iijiyometri ezininzi ngenxalenye nganye njengoko zihamba ngeendlela ezahlukeneyo zokufa. Obu buchule bufaneleka kakhulu kumthamo ophezulu kunye namalungu amakhulu afana nalawo akwishishini leemoto. Ukutshintshela isitampu sokufa yinkqubo efanayo, ngaphandle kokuba isitampu sokufa esiqhubekayo sibandakanya icwecwe elincanyathiselwe kumcu wesinyithi otsalwa kuyo yonke inkqubo. Ukutshintshela kufa isitampu kususa iworkpiece kwaye iyihambise ecaleni kweconveyor.

- I-Deep Draw Stamping yenza izitampu ezinemingxuma enzulu, njengoxande abavalelweyo. Le nkqubo idala iziqwenga eziqinileyo ukususela ekubeni ukuguqulwa okugqithisileyo kwesinyithi kucinezela isakhiwo sayo kwifom ye-crystalline ngakumbi. Ukutsala isitampu esisemgangathweni, okubandakanya ukufa okunzulu okusetyenziselwa ukubumba isinyithi, kuyasetyenziswa ngokuqhelekileyo.

- I-Fourslide Stamping imilo yamalungu ukusuka kwii-asi ezine endaweni yokusuka kwicala elinye. Le ndlela isetyenziselwa ukwenza iindawo ezincinci ezintsonkothileyo ezibandakanya izinto zombane ezifana nezihlanganisi zebhetri yefowuni. Ukubonelela ngokuguquguquka okuthe kratya koyilo, iindleko ezisezantsi zemveliso, kunye namaxesha okwenziwa akhawulezayo, isitampu se-fourslide sithandwa kwi-aerospace, ezonyango, kwimizi-mveliso yeemoto kunye neye-elektroniki.

- I-Hydroforming yinguquko yesitampu. Sheets zibekwe kwi die kunye imilo ezantsi, lo gama imilo eliphezulu ibladder yeoli egcwalisa uxinzelelo oluphezulu, ngokucinezela isinyithi kwimilo esezantsi die. Amalungu amaninzi anokwenziwa i-hydroformed ngaxeshanye. I-Hydroforming bubuchule obukhawulezayo nobuchanekileyo, nangona ifuna ukufa kwe-trim ukusika iinxalenye kwiphepha emva koko.

- Ukuvala kusika amaqhekeza kwiphepha njengenyathelo lokuqala ngaphambi kokwenza. I-Fineblanking, inguqu yokugubungela, yenza ukusika okuchanekileyo kunye nemiphetho egudileyo kunye nomphezulu osicaba.

- I-Coining lolunye uhlobo lwe-blanking eyenza i-workpieces encinci engqukuva. Ekubeni kubandakanya amandla abalulekileyo ukwenza iqhekeza elincinci, yenza isinyithi sibe lukhuni kwaye sisuse ama-burrs kunye neencam ezirhabaxa.

- Ukubethelwa ngamanqindi sisichasi sokuvala; kubandakanya ukususa izinto kwi-workpiece endaweni yokususa izinto ukuze wenze i-workpiece.

- I-Embossing idala uyilo lwe-dimensional-dimensional kwintsimbi, mhlawumbi iphakanyiswe ngaphezu komhlaba okanye ngoluhlu lwee-depressions.

- Ukugoba kwenzeka kwi-axis enye kwaye kudla ngokusetyenziswa ukwenza iiprofayili kwi-U, V, okanye iimilo ze-L. Obu buchule buphunyezwa ngokucinezela elinye icala kunye nokugoba elinye phezu kwedayiti okanye ukucinezela isinyithi ukuba singene okanye sichasane nedayizi. Ukujija kukugobela iithebhu okanye iinxalenye zesixhobo somsebenzi endaweni yendawo yonke.

Ulawulo lomgangatho

Vickers isixhobo sobulukhuni.

Isixhobo sokulinganisa iprofayili.

Isixhobo se-Spectrograph.

Isixhobo sokulungelelanisa ezintathu.

Umfanekiso wokuhanjiswa

Inkqubo yeMveliso

01. Uyilo lokungunda

02. Ukwenziwa kweMold

03. Ukulungiswa kweengcingo

04. Unyango lokushisa ngundo

05. Indibano yokungunda

06. Ukulungisa ingxaki yokungunda

07. Ukuhlawula imali

08. electroplating

09. Uvavanyo lweMveliso

10. Iphakheji

Inkqubo yeStamping

Inkqubo yonyango ngaphezuluiinxalenye ze-aluminiyam:

Kwishishini lesitampu, iinxalenye ze-aluminiyam zokugxiviza zikwayinxalenye yentsimbi eqhelekileyo. Iindlela zonyango eziqhelekileyo zomphezulu we-aluminiyam yezahlulo zezitampu zezi:

1.Anodizing

I-Anodizing inokwenza ngokufanelekileyo ukunqongophala kobunzima bomphezulu kunye nokumelana nokunxitywa kweendawo ze-aluminiyam. Isenokwandisa kakhulu ixesha lokusetyenziswa kweengxenye ze-aluminium stamping kwaye wenze imveliso ibonakale intle ngakumbi. Namhlanje, i-anodizing iye yaba yindlela yonyango ehlala isetyenziswa ngaphezulu kwiimveliso ze-aluminiyam. I-Anodizing ibhekisela kwi-electrochemical oxidation yesinyithi okanye i-alloys. I-aluminium kunye ne-alloys yayo yenza ifilimu ye-oxide kwimveliso ye-aluminium (i-anode) ngenxa yempembelelo yombane osetyenziswayo kwi-electrolyte ehambelanayo kunye neemeko ezithile zenkqubo.

2.Ukuqhushumba kwesanti

I-Sandblasting ngokuqhelekileyo yinkqubo ephakathi yonyango lomphezulu we-aluminiyam ye-stamping parts. Emva kokuba iinxalenye ze-aluminiyam zestampu ziqhutyelwe yisanti, i-surface burrs kunye namabala e-oyile anokususwa ngempumelelo. Inokuphucula ukucoceka komphezulu we-aluminiyam ye-stamping parts. Ngokulawula izinto eziqhumayo, iindawo ezahlukeneyo zinokufumaneka kwaye uburhabaxa bemveliso bunokwandiswa. Ukusebenza kwemveliso kunokuphuculwa kakhulu. Kwinkqubo elandelayo yonyango lomphezulu, ukunamathela phakathi kweendawo zokuthambisa i-aluminium kunye nokwaleka kunokwandiswa kakhulu, okwenza imveliso ibe yomelele kwaye ihle.

3. Unyango lokumenyezwa

Amacandelo e-aluminium epholisiweyo anokuthi asondele kwimpembelelo yesibuko, ephucula kakhulu ibakala kunye ne-aesthetics yemveliso. Nangona kunjalo, ngenxa yeempawu zeemveliso ze-aluminiyam, izitampu ze-aluminium zifuna ukukhazimliswa okuncinci. Ukuba akukho lunye unyango olungaphezulu lwenziwa emva kokupolisha, ukuqina kwemveliso kuya kuchaphazeleka. Ngaphezu koko, emva kokuba iinxalenye ze-aluminiyam ziphuculwe, kunzima ukugcina umphumo wesipili ixesha elide. Ngoko ke, ukuba isiphumo sesibuko siyafuneka, kuyacetyiswa ukuba kusetyenzisweyenziwe ngentsimbi eshayinayonjengemathiriyeli yemveliso.

4. Ukwenziwa komzobo wocingo

Zininzi iindidi zezitampu ze-aluminiyam ezibrashwayo, ezona zixhaphakileyo ngumzobo othe ngqo, umzobo osisiphithiphithi, umzobo ojikelezayo kunye nomzobo wokuzoba. Emva kokuba iinxalenye ze-aluminiyam zitsalwa ngocingo, amanqaku acacileyo nathambileyo angabonwa kumphezulu, kwaye imveliso inika abantu amava okubonwa kweepateni zesilika ezikhanyayo.

Aluminiyam izahlulo isitampu ngokusisiseko kufuna unyango umphezulu emva processing, kodwa indlela yonyango ekhethiweyo ixhomekeke kwiimfuno ezithile umthengi. Ukungabikho kwesicelo somthengi, i-anodizing idla ngokungagqibekanga.

Kutheni ukhetha i-Xinzhe yeendawo zokutywina zentsimbi yesiko?

UXinzhe yingcaphephe yentsimbi echwethezayo oyindwendwelayo. Ukukhonza abathengi kwihlabathi liphela, besisebenza ngokucokisekileyo kwisitampu sentsimbi phantse iminyaka elishumi. Amagcisa ethu okubumba anetalente ekhethekileyo kunye neenjineli zoyilo zizinikele, ziqeqeshekile, kwaye zineenqobo ezingqongqo zokusebenza.

Siyintoni isitshixo kwizinto esizifezileyo? Ixesha elinye lishwankathela impendulo: ukuqinisekiswa komgangatho kunye nespekthi. Kithina, iprojekthi nganye yahlukile. Siqhutywa ngumbono wakho, kwaye luxanduva lwethu ukuphumeza loo mbono. Sizama ukuqonda yonke inkalo yeprojekthi yakho ukuze sikufezekise oku.

Sibeka umzamo omkhulu ekufezekiseni umbono wakho xa sele siwubambile. Endleleni, kukho iindawo zokukhangela ezininzi. Oku kusenza siqinisekise ukuba imveliso egqityiweyo iyazanelisa ngokupheleleyo iimfuno zakho.

Iqela lethu ngoku ligxile ekuboneleleni ngeenkonzo zesiko lokutywina ngentsimbi kule mimandla ilandelayo:

Isitampu ngokwamanqanaba kuzo zombini izixa ezincinci nezinkulu

Ukunyathela okwesibini kwiibhetshi ezincinci

ukucofa ngaphakathi kokungunda

Ukucofa isibini okanye indibano

Umatshini kunye nokubunjwa

Ukuba ungathanda ulwazi oluthe kratya, ungalibazisi ukunxibelelana nathi.