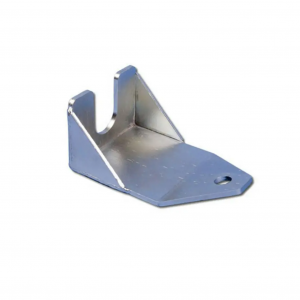

I-Custom Perforating Bend Stamping Component Part I-Galvanized Sheet Metal

Inkcazo

| Uhlobo lweMveliso | imveliso eyenzelwe wena | |||||||||||

| Inkonzo yokuma enye | Uphuhliso lokungunda kunye noyilo-ungenise iisampulu-ibhetshi imveliso-ukuhlola-umphezulu unyango-upakisho-unikezelo. | |||||||||||

| Inkqubo | isitampu, ukugoba, umzobo onzulu, ukwenziwa kwamaphepha esinyithi, ukuwelda, ukusika i-laser njl. | |||||||||||

| Izinto eziphathekayo | carbon steel, steel stainless, aluminiyam, ubhedu, intsimbi yagalvanized njl. | |||||||||||

| Imilinganiselo | ngokwemizobo yomthengi okanye iisampuli. | |||||||||||

| Gqiba | Ukupeyinta ukutshiza, i-electroplating, i-hot-dip galvanizing, i-powder coating, i-electrophoresis, i-anodizing, i-blackening, njl. | |||||||||||

| Indawo yesicelo | Amalungu omatshini, iindawo zoomatshini bezolimo, iinxalenye zoomatshini bobunjineli, iinxalenye zobunjineli bokwakha, izincedisi zegadi, iindawo zoomatshini ezinobume bendalo, iinxalenye zenqanawa, iinxalenye zeenqwelomoya, ukufakwa kwemibhobho, iinxalenye zezixhobo zehardware, iinxalenye zokudlala, iinxalenye ze-elektroniki, njl. | |||||||||||

Iintlobo zenkqubo yokugalela

1. Cyanide galvanizing: Ngaphandle kokuthintelwa ngenxa yenkxalabo yokusingqongileyo, icyanide galvanizing inemisebenzi emininzi. Umgangatho wemveliso ulungile xa usebenzisa isisombululo se-cyanide ephantsi (i-micro cyanide), kwaye ifaneleke ngokukodwa ukutshiza kombala.

2. I-Zincate galvanizing: Le ndlela yobugcisa iphuhliswe kwi-cyanide galvanizing kwaye ihlelwa ngamaqela amabini aphambili: uchungechunge lwe-"DE" ye-Radio kunye ne-Televishini ye-"DE" kunye ne-Wuhan Material Protection Institute's "DPE" series. Ulwakhiwo lwe-lattice yokwambathisa lulungele ukugqalwa kombala, lunokumelana ne-corrosion, kunye ne-columnar.

3. I-chloride galvanizing: ukuya kwi-40% yecandelo le-electroplating isebenzisa oku ngokubanzi. Ilungele isilivere okanye iblue passivation emhlophe, kwaye ifaneleke ngakumbi kunyango lomphezulu olandela ukusetyenziswa kwevanishi enyibilikayo emanzini.

4. I-sulfate galvanizing ayibizi kwaye ifanelekile ukufakwa ngokuqhubekayo kweengcingo, imicu, kunye nezinye izinto ezilula, ezityebileyo nezinkulu.

5. I-Hot-dip galvanizing: Ukuqinisekisa ukuba i-zinc liquid ibambelela kwiindawo ezicwecwe ngokulinganayo kunye ne-densely, gcoba iindawo kuqala ukuze ususe i-oxide layer. Emva koko, zifake kwi-zinc liquid kwi-tank ye-plating ye-hot-dip.

6. I-Electro-galvanizing: Umphezulu wezixhobo ezicandiweyo uyacocwa ukuze kususwe ukungcola, okucoliweyo, kunye ne-oyile kunye nothuli olususwe ngaphambi kokuba lufakwe kwisisombululo setyuwa yezinki. Izahlulo ezicandiweyo zifakwe kwi-zinc layer ngokubonga kwi-electrolytic reaction.

7. I-galvanizing ye-Mechanical: I-coating yenziwe ngokungqubuzana ngomatshini kunye nekhemikhali ye-zinc adsorbing powder kumacandelo acwecwe.

8. I-galvanizing etyhidiweyo: Intsimbi igqunywe ngumaleko we-zinc etyhidiweyo ngokuyifaka kwi-melted ye-aluminium alloy, eyandisa ukuguga kunye nokuxhathisa ukubola.

Zonke ezi nkqubo zikhankanywe ngasentla zineenzuzo kunye neengxaki zazo, kwaye zifanelekile kwiimeko ezithile zesicelo kunye neemfuno.

Ulawulo lomgangatho

Vickers isixhobo sobulukhuni.

Isixhobo sokulinganisa iprofayili.

Isixhobo se-Spectrograph.

Isixhobo sokulungelelanisa ezintathu.

Umfanekiso wokuhanjiswa

Inkqubo yeMveliso

01. Uyilo lokungunda

02. Ukwenziwa kweMold

03. Ukulungiswa kweengcingo

04. Unyango lokushisa ngundo

05. Indibano yokungunda

06. Ukulungisa ingxaki yokungunda

07. Ukuhlawula imali

08. electroplating

09. Uvavanyo lweMveliso

10. Iphakheji

Inkqubo yokugalela idiphu eshushu

I-galvanizing yindlela yonyango engaphezulu esetyenziselwa ukuthintela ukubola kunye nokongeza isibheno sobuhle ngokufaka umaleko we-zinc kumphezulu wesinyithi, i-alloys, kunye nezinye izinto. Ukugalela idiphu eshushu yeyona ndlela iphambili.

I-Zinc ibizwa ngokuba yintsimbi ye-amphoteric kuba inyibilika ngokulula kuzo zombini iiasidi kunye neealkali. Umoya owomileyo ubangela utshintsho oluncinci kwi-zinc. Kumphezulu we-zinc, umaleko oshinyeneyo wesiseko se-zinc carbonate uya kukhula emoyeni ofumileyo. I-Zinc inokumelana ne-corrosion ephantsi kwi-sulphur dioxide, i-hydrogen sulfide, kunye ne-atmospheres yaselwandle. Ingubo ye-zinc ichithwa ngokulula, ngakumbi kwiindawo ezinokushisa okuphezulu, ukufuma okuphezulu, kunye ne-organic acids.

I-Zinc inomlinganiselo oqhelekileyo we-electrode -0.76 V. I-Zinc yokugqoka i-anodic coating for substrates zetsimbi. Eyona njongo yayo iphambili kukumisa intsimbi ekudlekeni. Ikhono layo lokukhusela lihambelana ngokuthe ngqo kunye nobukhulu bengubo. Iimpawu zokuhombisa kunye nezikhuselayo ze-zinc zinokuphuculwa kakhulu ngokudlula, ukufa, okanye ukufaka isikhuselo seglosi.

FAQ

Umbuzo: Ngaba uyinkampani yokurhweba okanye umenzi?

A: Singumenzi.

Umbuzo: Uyifumana njani isicatshulwa?

A: Nceda uthumele imidwebo yakho (PDF, stp, igs, step...) kuthi nge-imeyile , kwaye usitshele izinto eziphathekayo, unyango olungaphezulu kunye nobungakanani, ngoko siya kwenza i-quotation kuwe.

Umbuzo: Ngaba ndingaodola i-1 okanye i-2 pcs yokuvavanya?

A: Ewe, kunjalo.

Q. Ngaba unokuvelisa ngokweesampuli?

A: Ewe, sinokuvelisa ngeesampulu zakho.

Umbuzo: Lingakanani ixesha lokuhambisa kwakho?

A: 7 ~ 15 iintsuku, kuxhomekeke ubungakanani odolo kunye nenkqubo imveliso.

Q. Ngaba uyazivavanya zonke iimpahla zakho phambi kokuhanjiswa?

A: Ewe, sinovavanyo lwe-100% ngaphambi kokunikezelwa.

Umbuzo: Ulenza njani ishishini lethu ixesha elide kunye nobudlelwane obuhle?

A:1. Sigcina umgangatho olungileyo kunye nexabiso elikhuphisanayo ukuqinisekisa ukuba abathengi bethu bayazuza;

2. Sihlonipha wonke umthengi njengomhlobo wethu kwaye senza ishishini ngokunyanisekileyo kwaye senze ubuhlobo nabo, kungakhathaliseki ukuba bavela phi.