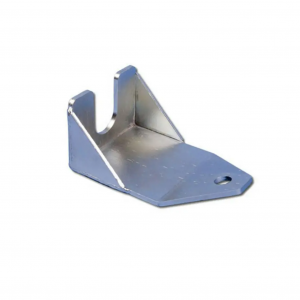

isixhobo Elevator ucango intloko yokukhwela isibiyeli izincedisi ilifti

Inkcazo

| Uhlobo lweMveliso | imveliso eyenzelwe wena | |||||||||||

| Inkonzo yokuma enye | Uphuhliso lokungunda kunye noyilo-ungenise iisampulu-ibhetshi imveliso-ukuhlola-umphezulu unyango-upakisho-unikezelo. | |||||||||||

| Inkqubo | isitampu, ukugoba, umzobo onzulu, ukwenziwa kwamaphepha esinyithi, ukuwelda, ukusika i-laser njl. | |||||||||||

| Izinto eziphathekayo | carbon steel, steel stainless, aluminiyam, ubhedu, intsimbi yagalvanized njl. | |||||||||||

| Imilinganiselo | ngokwemizobo yomthengi okanye iisampuli. | |||||||||||

| Gqiba | Ukupeyinta ukutshiza, i-electroplating, i-hot-dip galvanizing, i-powder coating, i-electrophoresis, i-anodizing, i-blackening, njl. | |||||||||||

| Indawo yesicelo | Amalungu omatshini, iindawo zoomatshini bezolimo, iinxalenye zoomatshini bobunjineli, iinxalenye zobunjineli bokwakha, izincedisi zegadi, iindawo zoomatshini ezinobume bendalo, iinxalenye zenqanawa, iinxalenye zeenqwelomoya, ukufakwa kwemibhobho, iinxalenye zezixhobo zehardware, iinxalenye zokudlala, iinxalenye ze-elektroniki, njl. | |||||||||||

Iinzuzo

1. Ngaphezu kweminyaka elishumi yamava kurhwebo lwamazwe ngamazwe.

2. Nikeza ivenkile enendawo enye kuyo yonke into ukusuka ekuhanjisweni kwemveliso ukuya kuyilo lokungunda.

3. Ukuhanjiswa ngokukhawuleza, kuthatha phakathi kwe-30 kunye neentsuku ze-40. ngaphakathi konikezelo lweveki.

4. Ulawulo lwenkqubo engqongqo kunye nolawulo lomgangatho (umenzi kunye nefektri enesatifikethi se-ISO).

5. Iindleko ezifikelelekayo ngakumbi.

6. Izakhono: Ngaphezu kweminyaka elishumi yamava, umzi-mveliso wethu ugximfize isinyithi.

Ulawulo lomgangatho

Vickers isixhobo sobulukhuni.

Isixhobo sokulinganisa iprofayili.

Isixhobo se-Spectrograph.

Isixhobo sokulungelelanisa ezintathu.

Umfanekiso wokuhanjiswa

Inkqubo yeMveliso

01. Uyilo lokungunda

02. Ukwenziwa kweMold

03. Ukulungiswa kweengcingo

04. Unyango lokushisa ngundo

05. Indibano yokungunda

06. Ukulungisa ingxaki yokungunda

07. Ukuhlawula imali

08. electroplating

09. Uvavanyo lweMveliso

10. Iphakheji

Inkqubo yeStamping

Inkqubo yesinyithi yesitampu yindlela ebalulekileyo yokulungisa isinyithi kwaye isetyenziswa ngokubanzi kwiinkalo ezahlukeneyo zokwenza:

1. Inkcazo kunye nomgaqo-siseko: Inkqubo yokugxilwa kwesinyithi yindlela yokucubungula esebenzisa uxinzelelo ukuguqula i-metal sheets kwi-mold. Umgaqo osisiseko kukusebenzisa i-punches kunye nokufa ukwenza uxinzelelo kwi-metal sheets ukuze kubangele ukuguqulwa kweplastiki, ngaloo ndlela kufumaneke iindawo zetsimbi ezinemilo efunekayo, ubungakanani kunye nokusebenza.

2. Uyilo lokubumba: Isikhunta siyinxalenye ephambili yenkqubo yesitampu yesinyithi, kwaye ukuyila kwayo kuchaphazela ngokuthe ngqo umgangatho wemveliso kunye nokusebenza kakuhle kwemveliso. Uyilo lokungunda kufuneka luqwalasele ubume, ubukhulu, iimfuno zokuchaneka kwemveliso, kunye nemithetho yokusebenza kunye nokuguqulwa kwezinto.

3. Izixhobo zesitampu kunye nokukhethwa: Izixhobo zokubetha zibandakanya iipuntshi, oomatshini bokushicilela, oomatshini bokushicilela be-hydraulic, njl.njl. Ukukhetha izixhobo ezifanelekileyo zesitampu kufuna uqwalaselo olubanzi olusekwe kwizinto ezifana nobukhulu bemveliso, ubukhulu, imathiriyeli kunye nebhetshi yokuvelisa.

4. Inkqubo yesitampu kunye nokwahlulahlula: Inkqubo yesitampu yesinyithi ngokuqhelekileyo ibandakanya ukuvala, ukubethelwa, ukugoba, ukuzotywa okunzulu, ukusika kunye nezinye iinkqubo. Ngokuxhomekeke kwiimfuno ezahlukeneyo zemveliso kunye neempawu zezinto eziphathekayo, ukudityaniswa kwenkqubo yesitampu eyahlukeneyo kunokukhethwa.

5. Iiparamitha zenkqubo kunye nokuphucula: Iiparamitha zenkqubo zibandakanya isantya sesitampu, uxinzelelo, ubushushu, njl. Ukukhethwa kunye nokulungiswa kwezi parameters kubaluleke kakhulu ekuphuculeni umgangatho wemveliso, ukunciphisa ukusetyenziswa kwamandla kunye nokuphucula ukusebenza kakuhle kwemveliso.

6. Iziphene eziqhelekileyo kunye nezisombululo: Ngexesha lenkqubo yesitampu yesinyithi, ezinye iziphene eziqhelekileyo zinokuthi zenzeke, ezifana nekhefu, i-deformation yeplastiki engalinganiyo, imibimbi, i-burrs, njl. Ukujongana nezi ziphene, izisombululo ezihambelanayo kufuneka zithathwe, ezifana nokuphucula i-mold design, ukulungiswa kweeparameters zenkqubo, ukuphucula umgangatho wezinto eziphathekayo, njl.

7. Iinkalo zesicelo: Iteknoloji ye-Metal stamping isetyenziswa ngokubanzi kwiimoto, i-electronics, izixhobo zasekhaya, i-aerospace kunye nezinye iindawo. Inokuvelisa iinxalenye zentsimbi zeemilo ezahlukeneyo kunye nobukhulu ukuhlangabezana neemfuno zamashishini ahlukeneyo.

Inkqubo yesinyithi yesitampu yindlela ebalulekileyo yokucubungula isinyithi kunye nethemba lokusetyenziswa ngokubanzi. Ngokuqhubeka nokuphucula uyilo lokungunda, iiparamitha zenkqubo kunye neenkqubo zemveliso, umgangatho wemveliso unokuphuculwa, iindleko zemveliso ziyancitshiswa, kunye nokutshintsha iimfuno zemarike.

FAQ

1.Q: Ithini indlela yokuhlawula?

A: Siyayamkela i-TT (i-Bank Transfer), L/C.

(1. Ngemali iyonke engaphantsi kwe-US$3000, 100% kwangaphambili.)

(2. Ngexabiso lilonke elingaphezu kwe-US$3000, i-30% kwangaphambili, intsalela ithelekiswa noxwebhu lwekopi.)

2.Q: Uphi umzi-mveliso wakho?

A: Umzi-mveliso wethu useNingbo, Zhejiang.

3.Q: Ngaba ubonelela ngeesampuli zamahhala?

A: Ngokwesiqhelo asiboneleli ngeesampuli zasimahla. Kukho isampuli yeendleko ezinokubuyiselwa emva kokuba wenze iodolo.

4.Q: Yintoni odla ngokuyithumela ngayo?

A: Uthutho lomoya, uthutho lolwandle, ukuvakalisa yeyona ndlela yokuthunyelwa ngenxa yobunzima obuncinci kunye nobukhulu beemveliso ezichanekileyo.

5.Q: Andinawo umzobo okanye umfanekiso okhoyo kwiimveliso zesiko, ngaba ungayila?

A: Ewe, sinokwenza olona yilo lufanelekileyo ngokuhambelana nesicelo sakho.