Ixesha elifutshane eliKhokelayo leSiko leMetal yeSitampu sokugoba uMvelisi weMveliso eChina

Ngenkqubo epheleleyo yenzululwazi yolawulo lomgangatho, umgangatho olungileyo kunye nokholo olulungileyo, siphumelele igama elihle kwaye sahlala kweli thafa leXesha Elifutshane leSiko leSiko leMetal yeSitampu sokugoba uMvelisi weMveliso eTshayina, Siyabamkela ngokufudumeleyo abathengi, imibutho yamashishini amancinci kunye namaqabane avela kulo lonke ihlabathi ukuba aqhagamshelane nathi kwaye afumane intsebenziswano kwiinzuzo ezifanayo.

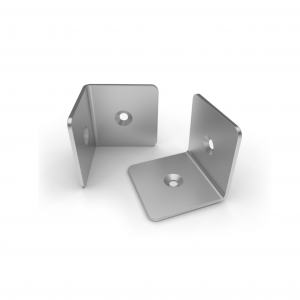

Ngenkqubo epheleleyo yolawulo lomgangatho wenzululwazi, umgangatho olungileyo kunye nokholo oluhle, siphumelela igama elihle kwaye sahlala kweli candeloIiMveliso zokugoba isinyithi, iinxalenye zokugoba zentsimbi, iiMveliso zeNtsimbi eNgatyiwayo, Ngoku, sizama ukungena kwiimarike ezintsha apho singenakho ubukho kunye nokuphuhlisa iimarike esinazo sele zingenile. Ngenxa yomgangatho ophezulu kunye nexabiso elikhuphisanayo, siya kuba yinkokeli yemarike, nceda unganqikazi ukuqhagamshelana nathi ngefowuni okanye nge-imeyile, ukuba unomdla kuyo nayiphi na imveliso yethu.

Inkcazo

Inkcazo

Ngokubanzi, zimbini iindlela zokugoba imibhobho yentsimbi, enye yindlela yokugoba ebandayo, kwaye enye yindlela yokugoba eshushu.

Indlela yokuqala: indlela yokugoba ebandayo, le ndlela isebenzisa ngokubanzi umatshini wokugoba ukwenza imiqulu emininzi ukufezekisa injongo yethu yokugoba. Nangona kunjalo, le ndlela ayifezekanga. Ngenxa yobukhulu obunqamlekileyo bombhobho wensimbi, i-angle yokugoba ngokubanzi i-1CM-5CM kuphela. Ngapha koko, igophe lincinci kakhulu, kwaye ububanzi bombhobho wentsimbi kulula kakhulu ukugqwesa.

Indlela yesibini: indlela yokugoba eshushu, le ndlela idla ngokuzalisa umbhobho wentsimbi engenasici ngesanti, kwaye emva koko usebenzise ubushushu obuphezulu ukunyanga nokwelula i-workpiece. Xa kuthelekiswa nendlela yokugoba ebandayo, le ndlela yeyona ifanelekileyo, kodwa ayifezekanga, oko kukuthi, iindleko zokusetyenzwa kwale ndlela ziphezulu kakhulu, kwaye ayifanelekanga ngokubanzi ukwenziwa komgangatho omkhulu.

Ngokuqhelekileyo, okukhona ipleyiti yentsimbi ijiyile, kokukhona amandla okugoba kufuneka sihlengahlengise xa sihlengahlengisa izixhobo zokugoba; ukongeza, phantsi kobungakanani beyunithi yokugoba yentsimbi engenakutyiwa, kokukhona umthamo wokuzibamba wepleyiti yentsimbi, ubukhulu bobude bayo Ukuba mncinci umyinge, kokukhona amandla okugoba kunye ne-engile yokugoba.

Ukuba ubukhulu bepleyiti yensimbi engenasici buhambelana neradiyasi yokugoba kumzobo woyilo, ngoko ke ubungakanani obandisiweyo bomsebenzi wethu ogobileyo kufuneka bube bubunzima becala elinekona ekunene dibanisa okanye thabatha ipleyiti enomaleko kabini, ukuze kuhlangatyezwane neemfuno zoyilo oluchanekileyo. Inqaku lokugqibela elimele liqwalaselwe kukuba amandla amakhulu emveliso yensimbi engenasici, inkulu uluhlu lokubuyisela i-elastic. Ukuba i-angle ye-90-degree yecandelo lokugoba inokufumaneka, i-angle ye-knife yokucinezela kufuneka yenzelwe ukuba ibe yincinci.

Imibuzo edla ngokubuzwa malunga nemibhobho yentsimbi engatyiwayo yokusetyenzwa kwentsimbi:

Kumsebenzi wethu wokugoba umbhobho wensimbi engenasici, iintanda zihlala zivela phezu kombhobho wensimbi. Le meko ngokuqhelekileyo emva kokuba umbhobho wensimbi woluliwe kwaye ukhubazeke, xa uchithwa, kwaye emva kwempembelelo okanye i-vibration stretching deformation. Ukuba ayiphathwanga ngexesha, iya kuba kwi Iba nkulu emva kokuyisebenzisa okwethutyana. Esona sizathu sesokuba insimbi engenastainless ine-ductility ephantsi, imodyuli ephezulu elastiki, kunye nesalathiso esikhulu sokuqina, kunye nenqanaba lokuguqulwa kweplastiki ukusuka ekuyekeni ukuya ekuqhekekeni emva kokugoba lifutshane.

Ngokohlelo lwensimbi engenasici, sifumene ukuba isalathisi esibandayo se-austenitic steel stainless steel siphezulu kakhulu. Yimathiriyeli enokumetastable, kwaye iya kungena kwinguqu yesigaba xa ikhubazekile, kwaye kunokwenzeka kakhulu ukwenza isakhiwo se-martensitic. Esi sakhiwo si-brittle kakhulu, ngoko kulula ukuqhekeka. Ngokubanzi, kukho iindlela ezimbini zokugoba imibhobho yentsimbi, enye yindlela yokugoba ebandayo, kwaye enye yindlela yokugoba eshushu.

Indlela yokuqala: indlela yokugoba ebandayo, le ndlela isebenzisa ngokubanzi umatshini wokugoba ukwenza imiqulu emininzi ukufezekisa injongo yethu yokugoba. Nangona kunjalo, le ndlela ayifezekanga. Ngenxa yobukhulu obunqamlekileyo bombhobho wensimbi, i-angle yokugoba ngokubanzi i-1CM-5CM kuphela. Ngaphaya koko, igophe lincinci kakhulu, kwaye ububanzi bombhobho wentsimbi kulula kakhulu ukuwuguqula.

Indlela yesibini: indlela yokugoba eshushu, le ndlela idla ngokuzalisa umbhobho wentsimbi engenasici ngesanti, kwaye emva koko usebenzise ubushushu obuphezulu ukunyanga nokwelula i-workpiece. Xa kuthelekiswa nendlela yokugoba ebandayo, le ndlela yeyona ifanelekileyo, kodwa ayigqibelelanga, oko kukuthi, iindleko zokusetyenzwa kwale ndlela ziphezulu kakhulu, kwaye ayifanelekanga ngokubanzi ukusetyenzwa ngezikrufu ezinkulu.

Imibuzo edla ngokubuzwa malunga nemibhobho yentsimbi engatyiwayo yokusetyenzwa kwentsimbi:

Kumsebenzi wethu wokugoba umbhobho wensimbi engenasici, iintanda zihlala zivela phezu kombhobho wensimbi. Le meko ngokuqhelekileyo emva kokuba umbhobho wensimbi woluliwe kwaye ukhubazeke, xa uchithwa, kwaye emva kwempembelelo okanye i-vibration stretching deformation. Ukuba ayiphathwanga ngexesha, iya kuba kwi Iba nkulu emva kokuyisebenzisa okwethutyana. Esona sizathu sesokuba intsimbi engatyiwayo ine-ductility ephantsi, imodyuli ephezulu elastiki, kunye nesalathiso esikhulu sokuqina, kunye nenqanaba lokuguqulwa kweplastiki ukusuka ekuyekeleni ukuya ekuqhekekeni emva kokugoba lifutshane.

Ngokohlelo lwensimbi engenasici, sifumene ukuba isalathisi esibandayo se-austenitic steel stainless steel siphezulu kakhulu. Yimathiriyeli enokumetastable, kwaye iya kungena kwinguqu yesigaba xa ikhubazekile, kwaye kunokwenzeka kakhulu ukwenza isakhiwo se-martensitic. Esi sakhiwo sinobunkunkqele kakhulu, ngoko kulula ukuqhekeka. (izikrufu zokuzicofa zentsimbi/ izikrufu zokuzicofa) Ngenkqubo epheleleyo yolawulo lomgangatho wesayensi, umgangatho olungileyo kunye nokholo oluhle, siphumelele igama elihle kwaye sahlala kweli candelo ixesha elifutshane lokuKhokela iSheet yeMetal Stamped Ukugoba uMvelisi weMveliso e-China, Samkela ngokufudumeleyo abathengi kunye nabathengi behlabathi lonke ukuba banxibelelane nathi kunye nokunxibelelana nathi kwihlabathi liphela. iingenelo.

Ixesha elifutshane lokuKhokela eTshayina Sheet Metal Stamped Goving and Machinery Parts, Ngoku, sizama ukungena kwiimarike ezintsha apho singenabo khona kunye nokuphuhlisa iimarike esinazo sele zingenile. Ngenxa yomgangatho ophezulu kunye nexabiso elikhuphisanayo, siya kuba yinkokeli yemarike, nceda unganqikazi ukuqhagamshelana nathi ngefowuni okanye nge-imeyile, ukuba unomdla kuyo nayiphi na imveliso yethu.