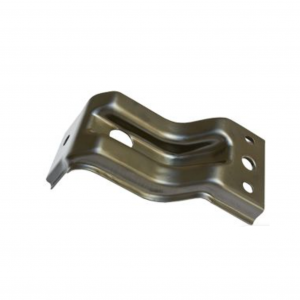

Isitampu sentsimbi yealuminiyam iinxalenye zentsimbi

Inkcazo

| Uhlobo lweMveliso | imveliso eyenzelwe wena | |||||||||||

| Inkonzo yokuma enye | Uphuhliso lokungunda kunye noyilo-ungenise iisampulu-ibhetshi imveliso-ukuhlola-umphezulu unyango-upakisho-unikezelo. | |||||||||||

| Inkqubo | isitampu, ukugoba, umzobo onzulu, ukwenziwa kwamaphepha esinyithi, ukuwelda, ukusika i-laser njl. | |||||||||||

| Izinto eziphathekayo | carbon steel, steel stainless, aluminiyam, ubhedu, intsimbi yagalvanized njl. | |||||||||||

| Imilinganiselo | ngokwemizobo yomthengi okanye iisampuli. | |||||||||||

| Gqiba | Ukupeyinta ukutshiza, i-electroplating, i-hot-dip galvanizing, i-powder coating, i-electrophoresis, i-anodizing, i-blackening, njl. | |||||||||||

| Indawo yesicelo | Amalungu omatshini, iindawo zoomatshini bezolimo, iinxalenye zoomatshini bobunjineli, iinxalenye zobunjineli bokwakha, izincedisi zegadi, iindawo zoomatshini ezinobume bendalo, iinxalenye zenqanawa, iinxalenye zeenqwelomoya, ukufakwa kwemibhobho, iinxalenye zezixhobo zehardware, iinxalenye zokudlala, iinxalenye ze-elektroniki, njl. | |||||||||||

Iinzuzo

1. Ngaphezu kweminyaka eyi-10yobungcali borhwebo lwaphesheya.

2. Ukubonelelainkonzo enye-stopukusuka kuyilo lokungunda ukuya kunikezelo lwemveliso.

3. Ixesha lokuhambisa ngokukhawuleza, malunga30-40 iintsuku. Isitokhwe kwiveki enye.

4. Ulawulo olungqongqo lomgangatho kunye nolawulo lwenkqubo (ISOumenzi oqinisekisiweyo kunye nefektri).

5. Amaxabiso afanelekileyo.

6. Ubuchwephesha, umzi-mveliso wethu unayongaphezulu kwe-10iminyaka yembali kwintsimi yentsimbi yesitampu sentsimbi.

Ulawulo lomgangatho

Vickers isixhobo sobulukhuni.

Isixhobo sokulinganisa iprofayili.

Isixhobo se-Spectrograph.

Isixhobo sokulungelelanisa ezintathu.

Umfanekiso wokuhanjiswa

Inkqubo yeMveliso

01. Uyilo lokungunda

02. Ukwenziwa kweMold

03. Ukulungiswa kweengcingo

04. Unyango lokushisa ngundo

05. Indibano yokungunda

06. Ukulungisa ingxaki yokungunda

07. Ukuhlawula imali

08. electroplating

09. Uvavanyo lweMveliso

10. Iphakheji

Iprofayile yekhampani

Njengomnye wabanikezeli abaphambili baseTshayina besitampu sentsimbi, i-Ningbo Xinzhe Metal Products Co., Ltd. igxile ekuveliseni iinxalenye zemoto, iinxalenye zoomatshini bezolimo, iinxalenye zobunjineli, iinxalenye zobunjineli bokwakha, izincedisi zehardware, iinxalenye zoomatshini bokusingqongileyo, iinxalenye zenqanawa, iinxalenye zenqwelomoya, ukufakwa kombhobho, izixhobo zehardware, iithoyi, kunye nezincedisi zombane, phakathi kwezinye izinto.

Omabini amaqela azuza kubuchule bethu bokuqonda ngakumbi imarike ekujoliswe kuyo kwaye anike iingcebiso ezisebenzayo eziza kunceda abathengi bethu bafumane isabelo esikhulu semarike. Sizinikezele ekunikeni abathengi bethu inkonzo ebalaseleyo kunye neenxalenye zeprimiyamu ukuze sizuze ukuthenjwa. Ukuseka unxibelelwano oluhlala luhleli kunye nabathengi bangoku kwaye uqhubele phambili ishishini elitsha kumazwe angengomaqabane ukukhuthaza intsebenziswano.

Inkqubo ye-oxidation

La manyathelo alandelayo ahlala ebandakanyiwe kwinkqubo ye-oxidation:

1. Ukutya okukrwada: Sebenzisa imibhobho ukunika imathiriyeli ekrwada kwireactor ukuze kugcinwe ukulungelelana okufanelekileyo kwemathiriyeli ekrwada ngaphakathi.

2. Ukuphendula: Ukwenza i-oxidation reaction, yongeza i-oksijini kwi-reactor kwaye ulawule iiparamitha zokusabela (ezifana neqondo lokushisa, uxinzelelo, kunye nexesha lokuphendula).

3. Ukwahlulwa kwemveliso: Sebenzisa isipholile-moya ukupholisa imveliso esabelayo, uyijike isuke kwindawo enerhasi ibe lulwelo okanye imo eqinileyo, emva koko usebenzise isahluli ukwahlula iimveliso ezivela kumacandelo ahlukeneyo.

4. Ukuhlanjululwa: Ukuqinisekisa ukuba imveliso yokusabela ifikelela kubunyulu obuyimfuneko, yihlambulule.

5. Ukupakishwa: Emva kokuba iimveliso zihlanjululwe, zipakishwa ngokuhambelana nezikhokelo kunye nemigangatho ngaphambi kokuba zithengiswe kubaxhasi okanye zithunyelwe kwinqanaba elilandelayo lokucubungula.

Kwezinye izicelo ezithile, ezifana ne-semiconductor wafer processing, inkqubo ye-oxidation ibandakanya ukubonelela nge-oxidants (njengamanzi, i-oksijeni) kunye namandla okushisa kwi-silicon substrate ukwenza ifilimu ye-silicon dioxide (SiO2). Le filimu ye-oxide ikhusela i-wafer ngokuthintela ukuvuza kwangoku ekujikelezeni phakathi kweesekethe, ukuthintela ukusasazwa ngexesha lenkqubo yokufakelwa kwe-ion, kwaye isebenze njengefilimu echasene ne-etching ekhusela ukuphosa okuphosakeleyo ngexesha lenkqubo ye-etching.