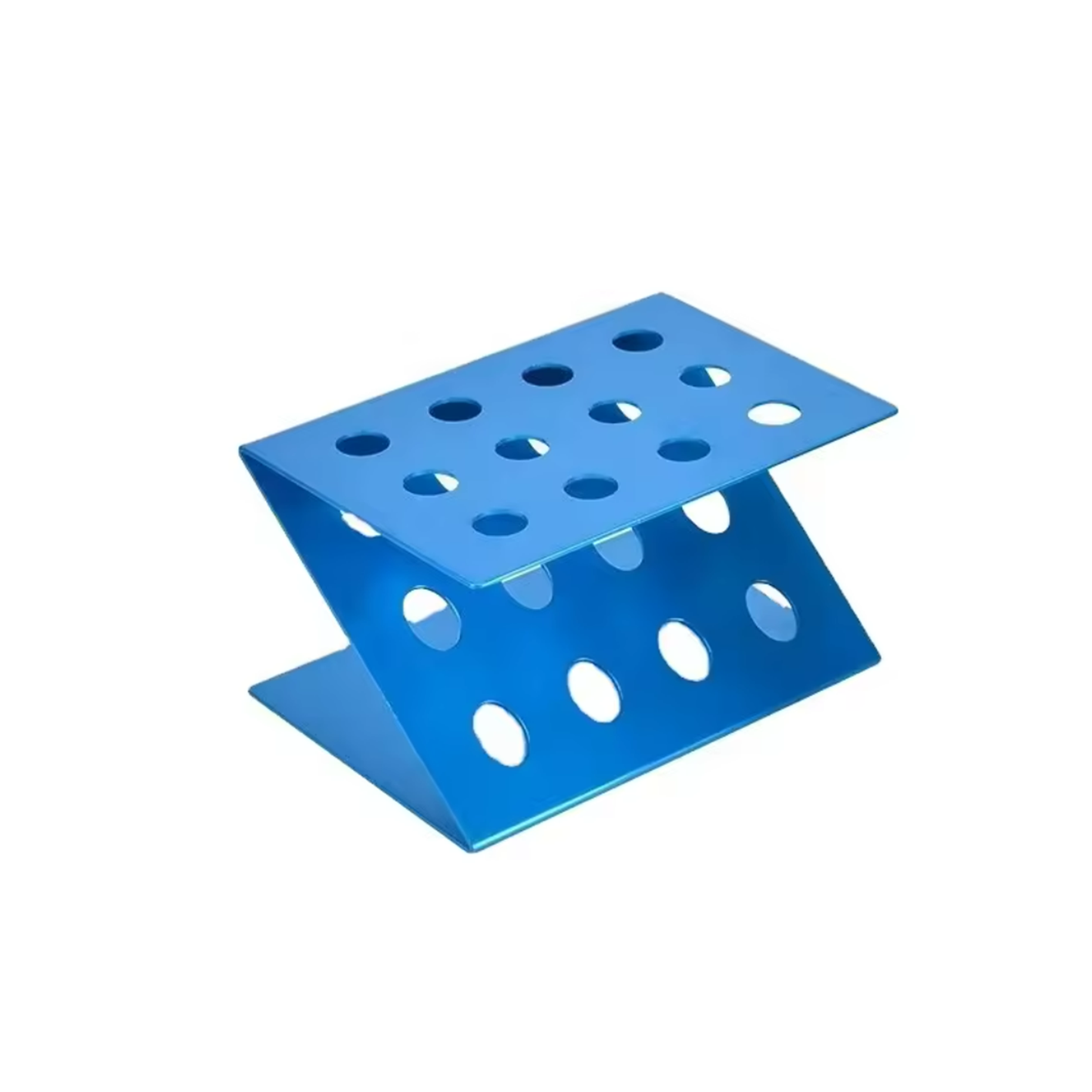

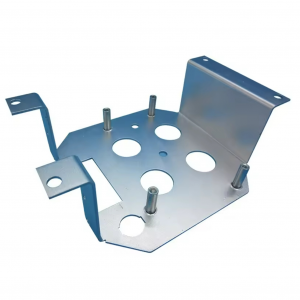

Ukuchaneka okuphezulu kweAluminiyam yeNsimbi eNgatyiwayo ye-SPHC SPCC yeShiti leSitampu seNtsimbi

Inkcazo

| Uhlobo lweMveliso | imveliso eyenzelwe wena | |||||||||||

| Inkonzo yokuma enye | Uphuhliso lokungunda kunye noyilo-ungenise iisampulu-ibhetshi imveliso-ukuhlola-umphezulu unyango-upakisho-unikezelo. | |||||||||||

| Inkqubo | isitampu, ukugoba, umzobo onzulu, ukwenziwa kwamaphepha esinyithi, ukuwelda, ukusika i-laser njl. | |||||||||||

| Izinto eziphathekayo | carbon steel, steel stainless, aluminiyam, ubhedu, intsimbi yagalvanized njl. | |||||||||||

| Imilinganiselo | ngokwemizobo yomthengi okanye iisampuli. | |||||||||||

| Gqiba | Ukupeyinta ukutshiza, i-electroplating, i-hot-dip galvanizing, i-powder coating, i-electrophoresis, i-anodizing, i-blackening, njl. | |||||||||||

| Indawo yesicelo | Amalungu omatshini, iindawo zoomatshini bezolimo, iinxalenye zoomatshini bobunjineli, iinxalenye zobunjineli bokwakha, izincedisi zegadi, iindawo zoomatshini ezinobume bendalo, iinxalenye zenqanawa, iindawo zokubhabha, izixhobo zombhobho, iinxalenye zesixhobo se-hardware, iinxalenye zokudlala, iinxalenye ze-elektroniki, njl. | |||||||||||

Iinzuzo

1. Ngaphezu kweminyaka eyi-10yobungcali borhwebo lwaphesheya.

2. Ukubonelelainkonzo enye-stopukusuka kuyilo lokungunda ukuya kunikezelo lwemveliso.

3. Ixesha lokuhambisa ngokukhawuleza, malunga30-40 iintsuku.Isitokhwe kwiveki enye.

4. Ulawulo olungqongqo lomgangatho kunye nolawulo lwenkqubo (ISOumenzi oqinisekisiweyo kunye nefektri).

5. Amaxabiso afanelekileyo.

6. Ubuchwephesha, umzi-mveliso wethu unayongaphezulu kwe-10iminyaka yembali kwintsimi yentsimbi yesitampu sentsimbi.

Ulawulo lomgangatho

Vickers isixhobo sobulukhuni.

Isixhobo sokulinganisa iprofayili.

Isixhobo se-Spectrograph.

Isixhobo sokulungelelanisa ezintathu.

Umfanekiso wokuhanjiswa

Inkqubo yeMveliso

01. Uyilo lokungunda

02. Ukwenziwa kweMold

03. Ukulungiswa kweengcingo

04. Unyango lokushisa ngundo

05. Indibano yokungunda

06. Ukulungisa ingxaki yokungunda

07. Ukuhlawula imali

08. electroplating

09. Uvavanyo lweMveliso

10. Iphakheji

Inkqubo ye-oxidation yeengxenye zesitampu zetsimbi

La manyathelo alandelayo ahlala ebandakanyiwe kwinkqubo ye-oxidation:

1. Ukutya okukrwada: Sebenzisa imibhobho ukunika imathiriyeli ekrwada kwireactor ukuze kugcinwe ukulungelelana okufanelekileyo kwemathiriyeli ekrwada ngaphakathi.

2. Ukuphendula: Ukwenza i-oxidation reaction, yongeza i-oksijini kwi-reactor kwaye ulawule iiparamitha zokusabela (ezifana neqondo lokushisa, uxinzelelo, kunye nexesha lokuphendula).

3. Ukwahlulwa kwemveliso: Sebenzisa isipholile-moya ukupholisa imveliso esabelayo, uyijike isuke kwindawo enerhasi ibe lulwelo okanye imo eqinileyo, emva koko usebenzise isahluli ukwahlula iimveliso ezivela kumacandelo ahlukeneyo.

4. Ukuhlanjululwa: Ukuqinisekisa ukuba imveliso yokusabela ifikelela kubunyulu obuyimfuneko, yihlambulule.

5. Ukupakishwa: Emva kokuba iimveliso zihlanjululwe, zipakishwa ngokuhambelana nezikhokelo kunye nemigangatho ngaphambi kokuba zithengiswe kubaxhasi okanye zithunyelwe kwinqanaba elilandelayo lokucubungula.

Kwizicelo ezithile ezikhethekileyo, njengokwenziwa kwe-wafer ye-semiconductor, inkqubo ye-oxidation ibandakanya ukusebenzisa amandla obushushu kunye ne-oxidants (ioksijini enjalo kunye namanzi) kwi-silicon substrate ukuze kuveliswe i-silicon dioxide (SiO2) yokwambathisa.Le filim yeoksidi isebenza njengomaleko ochasene ne-etching ukukhusela isiqwenga se-wafer ekufakweni okungafunekiyo ngexesha lenkqubo ye-etching, iyeke ukusasazwa ngexesha lenkqubo yokufakelwa kwe-ion, kwaye iyeke ukuvuza kwangoku ekudluleni kwiisekethe.

INKONZO YETHU

1. Iqela leR&D yobuchwephesha - Iinjineli zethu zibonelela ngoyilo olulodwa lweemveliso zakho ukuxhasa ishishini lakho.

2. IQela lokuLawula uMgangatho - Zonke iimveliso zivavanywa ngokungqongqo phambi kokuba zithunyelwe ukuqinisekisa ukuba zonke iimveliso zihamba kakuhle.

3. Iqela lolungiselelo olusebenzayo - ukupakishwa okulungiselelweyo kunye nokulandelela kwangethuba kuqinisekisa ukhuseleko de ufumane imveliso.

4. Iqela elizimeleyo emva kwentengiso-ebonelela ngeenkonzo zobungcali kwangexesha kubathengi iiyure ezingama-24 ngosuku.

5. Iqela lokuthengisa elichwepheshayo - olona lwazi lobuchwephesha luya kwabelwana nawe ukukunceda wenze ishishini ngcono nabathengi.