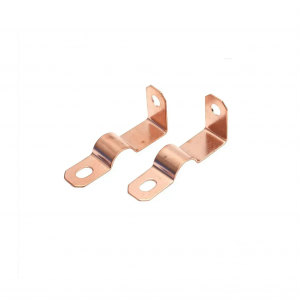

Isibiyeli seMetal Elevator eGalvanized Stamping Mounting Bracket

Inkcazo

| Uhlobo lweMveliso | imveliso eyenzelwe wena | |||||||||||

| Inkonzo yokuma enye | Uphuhliso lokungunda kunye noyilo-ungenise iisampulu-ibhetshi imveliso-ukuhlola-umphezulu unyango-upakisho-unikezelo. | |||||||||||

| Inkqubo | isitampu, ukugoba, umzobo onzulu, ukwenziwa kwamaphepha esinyithi, ukuwelda, ukusika i-laser njl. | |||||||||||

| Izinto eziphathekayo | carbon steel, steel stainless, aluminiyam, ubhedu, intsimbi yagalvanized njl. | |||||||||||

| Imilinganiselo | ngokwemizobo yomthengi okanye iisampuli. | |||||||||||

| Gqiba | Ukupeyinta ukutshiza, i-electroplating, i-hot-dip galvanizing, i-powder coating, i-electrophoresis, i-anodizing, i-blackening, njl. | |||||||||||

| Indawo yesicelo | Amalungu omatshini, iindawo zoomatshini bezolimo, iinxalenye zoomatshini bobunjineli, iinxalenye zobunjineli bokwakha, izincedisi zegadi, iindawo zoomatshini ezinobume bendalo, iinxalenye zenqanawa, iindawo zokubhabha, izixhobo zombhobho, iinxalenye zesixhobo se-hardware, iinxalenye zokudlala, iinxalenye ze-elektroniki, njl. | |||||||||||

Indima entsha yegalvanizing

Imisebenzi yentsimbi galvanizing ikakhulu ziquka la manqaku alandelayo:

Ikhusela kumhlwa kunye nomhlwa.Umaleko we-galvanized unokwahlula ngokufanelekileyo intsimbi ekudibaneni nomoya, umswakama kunye nezinye izinto eziphazamisayo, ukunciphisa kakhulu ukwenzeka kwe-corrosion, ngokukodwa kwiindawo ezifumileyo kunye ne-corrosion, le mpembelelo yokukhusela ibaluleke kakhulu.

Ukuphucula ubuhle.Umphezulu wesinyithi owenziwe ngesinyithi ubonisa i-metallic luster yesilivere-emhlophe, ephucula umgangatho wokubonakala kwemveliso kwaye ifanelekile kwizihlandlo ezineemfuno eziphezulu ze-aesthetics.

Yandisa amandla kunye nobunzima.Uluhlu oluqinileyo lwe-alloy olwenziwe ngexesha lenkqubo ye-galvanizing aluphuculi nje ubunzima bomhlaba wentsimbi, kodwa luphucula amandla ayo.

Kulula ukuqhubekeka.Intsimbi yegalvanized inomgangatho ogudileyo kwaye akulula ukugqwala, okwenza kube lula ukusika, ukuthunga, ukugoba kunye neminye imisebenzi yokucubungula, okuphucula ukusebenza kakuhle kunye nomgangatho wemveliso.

Ukunciphisa iindleko zokugcina.Ngenxa yokumelana nokugqwesa okuphezulu kunye nokuqina kwentsimbi ye-galvanized, ukuphindaphinda kokugcinwa kunye nokugcinwa kungancitshiswa ekusebenziseni ixesha elide, ngaloo ndlela kuncitshiswe iindleko ezipheleleyo zokusetyenziswa kwexesha elide.

Uluhlu olubanzi lwezicelo.Intsimbi yegalvanized isetyenziswa ngokubanzi kulwakhiwo, amandla ombane, ukuvelisa, ukuthutha kunye nezinye iindawo ngenxa yokusebenza kwayo kakuhle.

Ukongeza, nangona ukwenza igalvanizing kuneengenelo ezininzi, kukwanezinto ezingeloncedo, ezinje ngeendleko eziphezulu zemveliso, imiba enokwenzeka yongcoliseko lwendalo esingqongileyo, kunye nokususwa kwe-zinc okunokuthi kwenzeke kwiindawo ezithile ezigqithisileyo.Ngoko ke, xa ukhetha insimbi ene-galvanized, kufuneka uqwalasele iingenelo zayo, ukungonakali kunye nokufaneleka kwayo.

Ulawulo lomgangatho

Vickers isixhobo sobulukhuni.

Isixhobo sokulinganisa iprofayili.

Isixhobo se-Spectrograph.

Isixhobo sokulungelelanisa ezintathu.

Umfanekiso wokuhanjiswa

Inkqubo yeMveliso

01. Uyilo lokungunda

02. Ukwenziwa kweMold

03. Ukulungiswa kweengcingo

04. Unyango lokushisa ngundo

05. Indibano yokungunda

06. Ukulungisa ingxaki yokungunda

07. Ukuhlawula imali

08. electroplating

09. Uvavanyo lweMveliso

10. Iphakheji

Inkqubo yeStamping

Ubuchule bokungqinisisa ngesinyithi obubizwa ngokuba ngumzobo onzulu busetyenziswa ukubumba amashiti entsimbi abe luluhlu lweziqendu ezingenanto, ezilinganayo nge-axially.Le nkqubo yesitampu idala iimilo zecylindrical, nangona inokwenza izinto ezifana neebhokisi.Izinto ezininzi zemizi-mveliso kunye nezasekhaya, ezinje ngeesinki, iigriddles, izifakelo zemibhobho yamanzi, iinxalenye zemoto, iitoti zesiselo, kunye neecasings, zinokubunjwa ngokucolwa ngokunzulu isitampu.

Ukusebenzisa i-punching force, i-sheet yentsimbi itsalwa ngokukhawuleza kwigumbi lokufa kolu hlobo lwesitampu sesinyithi.Ipleyiti yentsimbi iqala ibekwe kumngundo owenziweyo.Iziphelo zephepha zigcinwe kwindawo yoxinzelelo lomphathi ongenanto.Emva koko, isixhobo sokunyathela esisebenza ngoomatshini sisebenzisa amandla e-axial kwiphepha lesinyithi, livumela i-workpiece ukuba iqukuqelele kumngxuma wokungunda kwaye iguqulwe ibe kwimilo efunekayo.

FAQ

Umbuzo: Ngaba uyinkampani yokurhweba okanye umenzi?

A: Singumenzi.

Umbuzo: Uyifumana njani isicatshulwa?

A: Nceda uthumele imizobo yakho (PDF, stp, igs, step...) kuthi nge-imeyile , kwaye usitshele izinto eziphathekayo, unyango olungaphezulu kunye nobungakanani, ngoko siya kwenza i-quotation kuwe.

Umbuzo: Ngaba ndingaodola i-1 okanye i-2 pcs yokuvavanya?

A: Ewe, kunjalo.

Q. Ngaba unokuvelisa ngokweesampuli?

A: Ewe, sinokuvelisa ngeesampulu zakho.

Umbuzo: Lingakanani ixesha lakho lokuhambisa?

A: 7 ~ 15 iintsuku, kuxhomekeke ubungakanani odolo kunye nenkqubo imveliso.

Q. Ngaba uyazivavanya zonke iimpahla zakho phambi kokuhanjiswa?

A: Ewe, sinovavanyo lwe-100% ngaphambi kokunikezelwa.

Umbuzo: Ulenza njani ishishini lethu ixesha elide kunye nobudlelwane obuhle?

A:1.Sigcina umgangatho olungileyo kunye nexabiso elikhuphisanayo ukuqinisekisa ukuba abathengi bethu bayazuza;

2. Sihlonipha wonke umthengi njengomhlobo wethu kwaye senza ishishini ngokunyanisekileyo kwaye senze ubuhlobo nabo, kungakhathaliseki ukuba bavela phi.